Continuation.

All of the above is more relevant to the preparatory operations before the direct process of heat treatment of sausage and meat products in smoking-cooking plants. Next, the attention of technologists is offered a description of the most frequently encountered problems in heat treatment and ways to eliminate them.

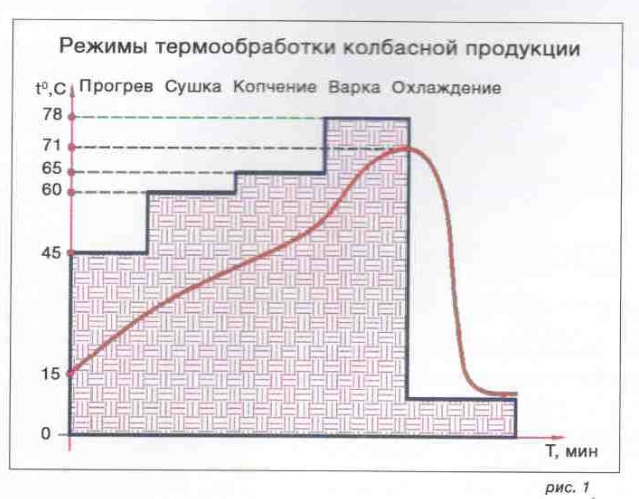

First I would like to recall the traditional sequence of stages of the entire heat treatment process, consisting of heating (sweating), drying, smoking and cooking (Fig. 1).

A feature of this process is the absence of sharp increases in temperature, i.e. Thermal loads on the surface of the product, and the most optimal time for each step. It is this sequence that makes it possible to obtain the best economic indicators from the point of view of the weight loss of finished products, the optimal operating time of the equipment in combination with the maximum possible taste characteristics of the products and their presentation in the modern smoking-cooking equipment.

Features of the stages of heat treatment.

Traditional heat treatment for all kinds of sausages begins with a step that is called differently in different interpretations (warming up, "sweating", "blushing", etc.), but in fact it means the same thing: heat treatment at low speeds Processes of heat transfer chamber - the product due to the use of low engine speed, the absence of moisture removal from the product surface due to closed flow dampers and air release and temperatures of intense ripening of minced meat prior to the beginning of protein coagulation. If you take into account that the temperature difference between the surface and the center of the product is from 5 °C to 10 °C, the natural temperature of the end of such a process will be 30-35 °C inside the product. And the time of this step (from 20 to 40 minutes) will be enough to complete all the biochemical processes responsible for the effective operation of all additives and spices, color formation and readiness for the next stages of heat treatment.

The purpose of the drying process is to prepare the surface of the product for smoking, i. e. Uniform drying of the shell with a constant decrease in humidity in the thermal chamber, and obtaining uniform color formation of the product. It should be noted that when drying under the term "color formation" is meant not the color of the finished product (it will be obtained, basically, after smoking), but a uniform intermediate shade of color depending on the composition of the mince. If there is insufficient color development, for almost all types of sausages, further smoking will not remove gray-earthy shades, which will spoil the ready-made products. In these cases, even with a dry shell, it is necessary to continue the drying process until the necessary color formation occurs. Weight loss in this case should be controlled by limiting the reduction in relative humidity in the thermal chamber to 25-30%.

The optimum drying parameters are: the temperature in the chamber is 55-65 °C and the process time is 30-50 min. The product temperature after the end of the drying process will be between 36-45 °C for sausages and 30-35 °C for whole-piece meat.

The next stage of heat treatment is smoking, in which the color of the finished product is formed and the preservation effect is obtained to increase the shelf life. Very often smoked w / sa sausages, delicacies and chicken products are carried out after cooking, tk. Cooking after smoking "washed off" the color, or it is lost with further storage. Such heat treatment leads to an increase in losses in the output of finished products due to the need for secondary drying of the product before smoking and reducing the shelf life due to the preservation of only the surface of the product. When cooking, after smoking, due to the high humidity of the air in the chamber and the increased air pressure, there is an intensive diffusion of smoke particles into the product, thereby preserving it in volume, not only over the surface.

It is very important to control the relative humidity during smoking. It should be between 45-75%. At a lower humidity, the smoke particles "cling" to the shell worse, at a higher one they are washed off with water drops.

The recommended temperature in the smoking room is 60-67 °C for sausage products and up to 70-72 °C for delicacy products. The time of smoking depends on the type of smoke generator, intensity of smoke, grade and humidity of chips and is 5-10 minutes. For cooked sausages and 15-25 minutes. For w / sa sausages and delicacies. The temperature in the product at the end of the smoking process can be in the range of 42-52 °C for different types of sausages and shells.

In cases where, for various reasons, after smoking after cooking, it is not possible to obtain uniform color formation of the product, or the color is lost during storage, so-called "wet smoking" is used, i.e. Smoking at high humidity - 75-90%. Such a technique is really effective in terms of color equalization, but it is much worse if we manage to get shades of colors of different varieties of cooked sausages and sardles in natural casings.

The final stage of heat treatment is cooking. On the one hand, cooking is not a difficult process - bringing the product to culinary readiness in conditions of high humidity and maximum permissible temperatures. But on the other hand, it is the management of the temperature and humidity parameters at this process that determines the desired presentation, affects the shelf life of the product and allows you to regulate the moisture losses of the finished product.

Boiling of cooked sausages in all kinds of casings should be carried out at maximum humidity by selection of the temperatures in the chamber, which will ensure the duration of the cooking process for 20-40 minutes for small and medium sausage diameters. The product availability times of less than 20 minutes can significantly affect product quality from the point of view of uniform warming up to the full volume of the product, which can lead to its souring during storage.

Semi-smoked and boiled-smoked sausages, as well as delicacy products are recommended.

|

Director of NPP Tekhinserv |

Dmitry Noskov |

|

Dnepropetrovsk |

office@techinserv.com |